Accelerate EV Innovation with Mendix-Powered Solutions

Deliver intelligent, scalable, and connected EV applications—faster—with low-code and AI.

Book a Free Consultation

MXTechies helps EV businesses overcome traditional IT bottlenecks using Mendix low code. With our solutions, you can:

Track materials, manufacturing data, performance history,

and recycling eligibility

in one unified

system.

Get real-time shop floor insights on WIP, machine utilization, operator tasks, and quality metrics.

Digitally manage vendor onboarding, document sharing, order visibility, and compliance through self-service

portals.

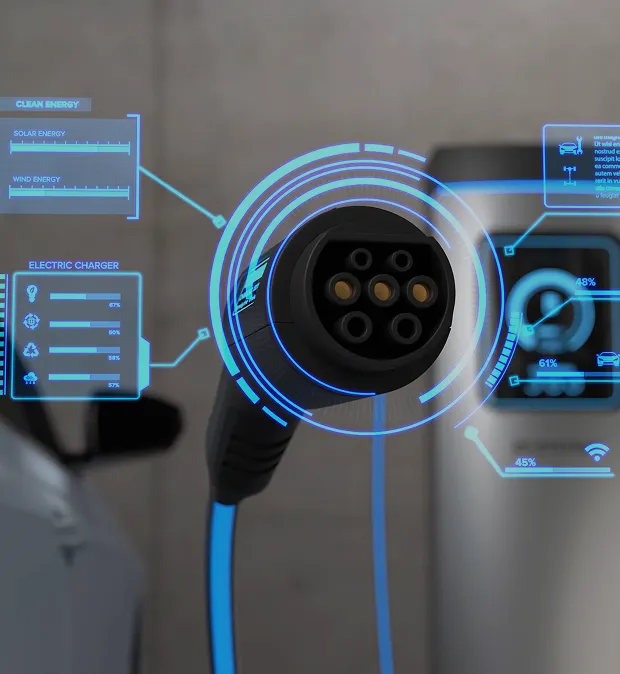

Monitor charging station health, manage maintenance tickets, and collect usage data across distributed locations.

Centralize and automate carbon footprint monitoring, safety compliance, and audit documentation.

Enable real-time configuration of EV specs, linked with backend systems for production, pricing, and fulfillment.

Modern EV operations need scalable technology that moves fast. Mendix, enhanced with GenAI, brings intelligent automation and seamless integrations to your digital initiatives.Key Capabilities:

EV manufacturers and suppliers using Mendix report measurable gains in speed, cost-efficiency, and compliance.

Results include:

60 to 70 percent faster rollout of digital applications

25 percent improvement in EV production throughput

20% increase in audit preparedness and ESG data transparency

Time savings of 30% on supplier integration and onboarding

What Sets Us Apart:

We work closely with your IT teams to ensure compliance, optimal performance, and seamless integration across your enterprise systems.

Yes. Mendix can centralize data from multiple sources to track battery materials, manufacturing records, performance analytics, and recycling eligibility throughout the lifecycle.

With prebuilt components and low-code development, you can launch a fully functional portal in 4 to 6 weeks, with support for onboarding, communication, and data integration.

Yes. Mendix applications support real-time data updates, work on mobile and tablet devices, and are optimized for both online and offline usage on the shop floor.

You can build apps for battery lifecycle management, production monitoring, ESG reporting, charging infrastructure maintenance, supplier collaboration, and more—without writing full code.